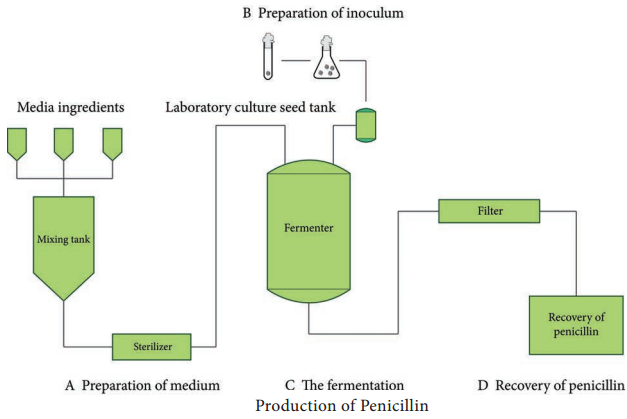

Medium is sterilized at high heat and high pressure, usually through a holding tube or sterilized together with the fermenter.

They provide the essential ions required for the fungus metabolic activity. Medium also consists of salts such as MgSO4, K3PO4 and sodium nitrates. A medium of corn steep liquor and glucose are added to the fermenter. The Penicillium chrysogenum usually contain its carbon source which is found in corn steep liquor and glucose. As stated above, this allows us to add the substrate to the reactor in small increments and to even change the substrate if we so desire.ġ. Use the fed-batch method to feed the culture.

Once the desired biomass has been achieved, starve (Limiting the amount of C and N available to the culture) the culture and induce the kind of stress conditions that trigger the production of the antibiotic. Media for this stage will be focussed on achieving maximum growth and biomass production.

The filter cloth gets into the cloth washing box through automatic error correction device, and gets newborn after both sides rinsing by high pressure water, then passes the tension roller to get back to the drum cover and starts new filtering process. The cake automatically discharges after going through discharge roller by driving of running cloth.

When working, the stock in the tank penetrate the filter cloth and get into the distribution valve by suction tube under the vacuum extraction, then go through the liquid outlet pipe into the gas-liquid separator and drain the solids form filter cake on the filter cloth. MKBF belt-discharge vacuum filter is the filter cloth running style solid & filtrate separation equipment. Special design and perfect performance make it suitable for thickening filter and dehydration for solid & filtrate with lower consistency, fine particle and high viscosity. It can achieve continuous suction filter, dehydration and automatic discharge on vacuum condition. MKBF belt-discharge rotary drum vacuum filter is developed and manufactured by absorbing European advanced technology. 1.Fermentation liquor (penicillin, for example) filtering dehydration in pharmaceutical industry 2.Metal hydroxide slurry, coal washing wastewater, copper ore filtering dehydration 3.Corn protein filtering dehydration 4.Wheat A starch filtering dehydration 5.Citric acid fermentation liquid filtering dehydration.

0 kommentar(er)

0 kommentar(er)